Plants for poussin processing

PLANTS FOR CAPACITIES UP TO 6,000 BPH Verderio plants for poussin processing are on the cutting edge of technology for a wholly automated production. Our equipment is complete, reliable, requires low maintenance, fits any production capacity and any existing plant.

COMPACT

-

All-in-one 200-bph processing plant

All-in-one 200-bph processing plant

-

All-in-one 500-bph processing plant

All-in-one 500-bph processing plant

STANDARD

-

Live handling

Live handling

-

Stunning, killing, scalding and plucking

Stunning, killing, scalding and plucking

-

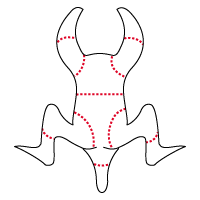

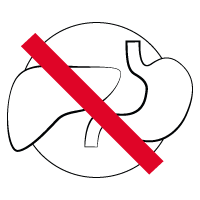

Evisceration

Evisceration

-

Cooling

Cooling

-

Cut-up

Cut-up

-

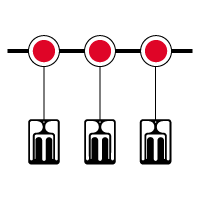

By-products evacuation

By-products evacuation

-

Plant construction

Plant construction

-

Software

Software